.... Belgium .... Wim Goes

Wim Goes

Glenn Murcutt Master Class 2006 : New Zealand Master Class 2008

[ coastal : sailing club : hospitality : steel : timber ]

Royal Belgian Sailing Club, Zeebrugge, Belgium : 2012

Wim Goes Architectuur

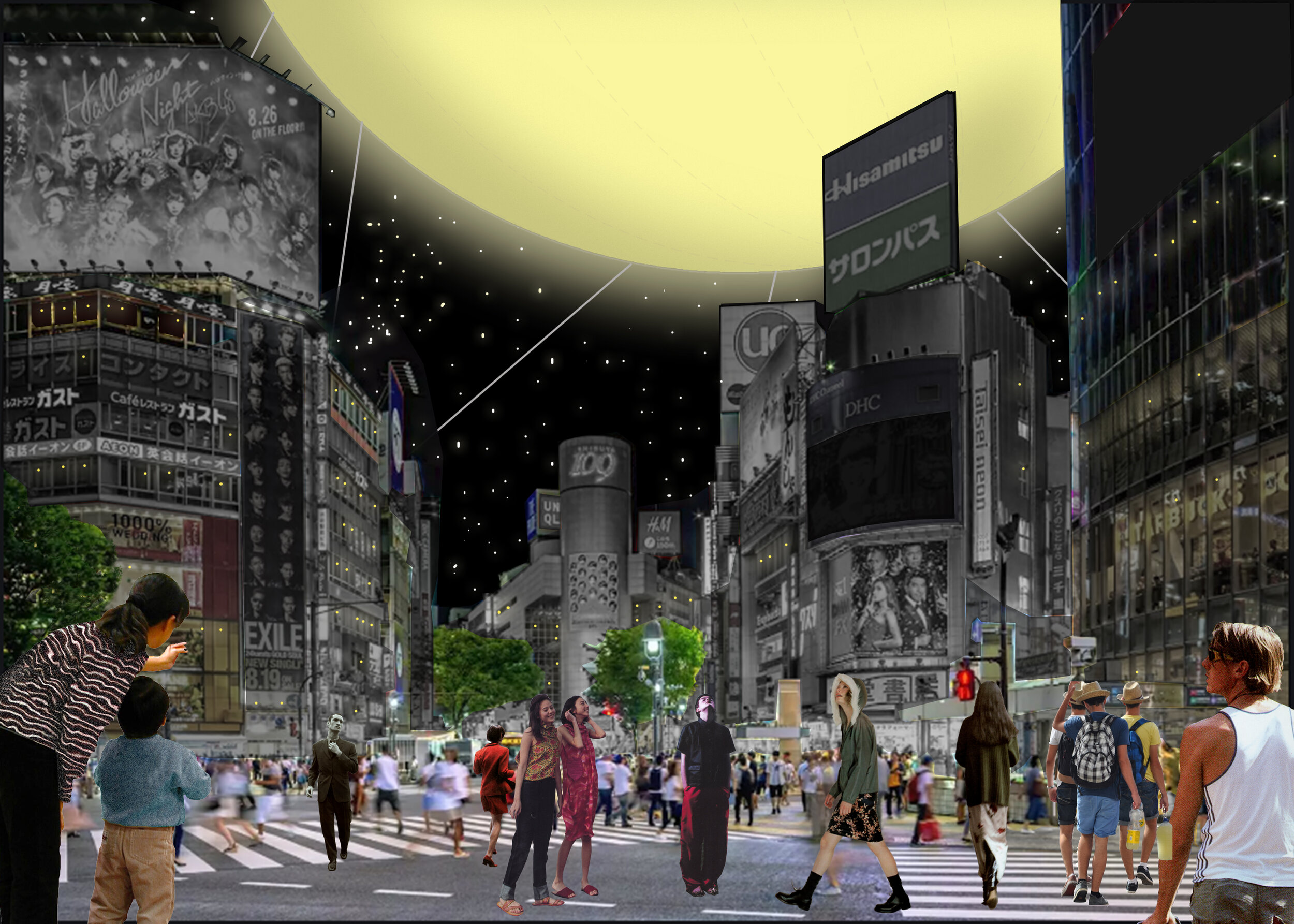

Between two maritime extremes, on the edge of a peninsula one finds a contemporary landscape. On the one side a container port with its inhuman scale generated by its activity, day and night, a proof of economy. On the other side a marina with its human scale and ergonomics, a source of history and sophistication, a proof of culture. In this tension field lays the Royal Belgian Sailing Club.

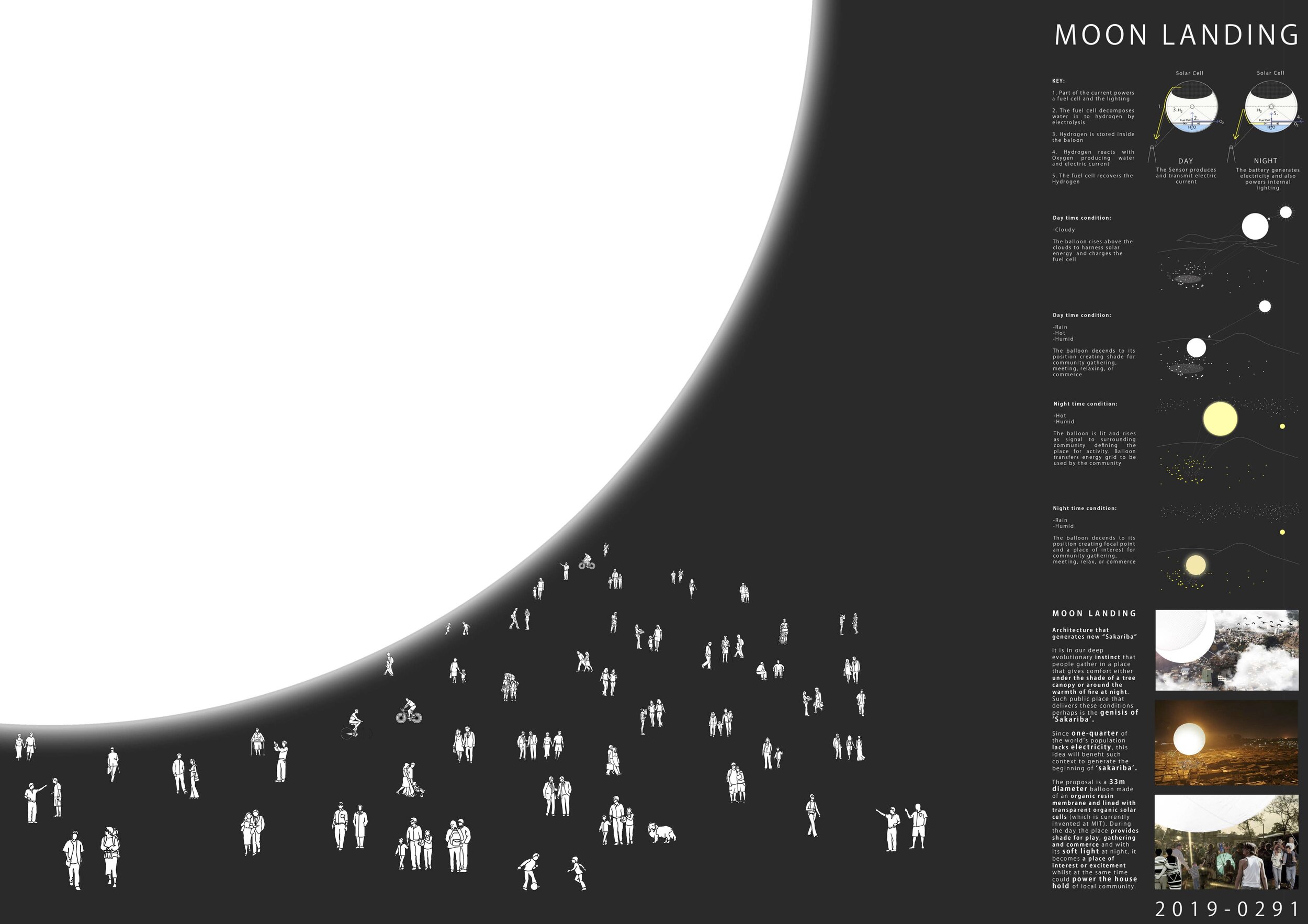

The building is made with a sailor’s logic. To make optimal use of the conditions the building does not carry any excess. The unheated glass passage serves as insulation layer (double skin and air) for the wooden core. It makes use of solar gains to heat up and trans ventilation for cooling and regulating the air quality though means of opening and/or closing windows. The wooden core is a heated space, and makes use of a geo thermal heat pump with under floor heating, ventilation and heat recuperation. The combination and interaction of these two systems makes possible many different scenarios depending on the social and meteorological conditions. In this way the wooden core and surrounding glass passage encourages a dynamic use of the building. The user steers the building on a journey, exploring an ever changing landscape.

The building was executed in 100 working days. In making this possible prefab elements were used. This includes laminated pine beams, single glazed steel windows and precast reinforced concrete walls.

The intrinsic qualities and logic of the materials are not tamed but freed giving dimension to the architecture. In this way multiple provisions were made to incorporate the movement (shrinking and expansion) of the timber structure. Timber beams are stacked on top of each other, and where they intersect they fit into each other in a cross joint, on top they are further strengthened by steel plates. Ease has been given above doors and between all joints to accommodate the material’s behaviour (movement). This is most visible where the steel frames of the façade join with the cantilevered timber beams by means of a slide connector, making it possible for the timber core to ‘breath’ independently. At this joint the windows transfer the wind loads onto the timber core resulting in them only having to support their own weight. The rails on the roof have trusses on which the steel accordion windows are hung.

There is a contrast in the behaviour of these two structures interacting in the building. The timber structure of the core hides the forces playing on it in its volume much like the hull of a ship, where the steel frames of the façade expresses them more like the cables and sails on a ship.

A third structure, the concrete basement only makes up part of the underground construction, where a concrete cast surrounding wall is filled in with prefabricated reinforced concrete interior walls. The windmills are fastened here in the concrete basement. The precast reinforced concrete plate that forms the roof of the basement is partially insulated below the timber core, but not under the passage. The polished terrazzo concrete with marine fossil grain is extended through both zones (core and passage). An L-profile on the perimeter acts as a perfect casting mould making possible refined result.

Team :

Wim Goes, Anja Houbaert, Laura Bown, Johannes Berry, Antonio Fernandez, Laura Van Kerkhove, Carmen Ojalvo Guiberteau, Eyukewe Nicolas Dogo, Tim De Messemaeker

Engineer : Studieburo Mouton

MEP Engineer : Raf De Herdt

Photos : Filip Dujardin

Wim Goes Architectuur -